While it’s likely you’ve heard of MDF, you may not know exactly what it stands for or how it is best used. MDF is an extremely common material for building or DIY projects, yet one that is often misunderstood when it comes to quality – largely due to its lower price point. If you’re partaking in a DIY or building project and are debating whether to use MDF, you’ve come to the right place. Here at Arnold Laver, we’re answering all of your MDF FAQ’s, running through exactly what MDF is and how it is made to the pros and cons of this versatile material.

What is MDF board?

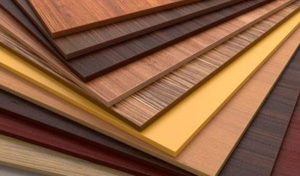

So, first things first; what is MDF board, and what does MDF stand for? MDF is a medium-density fiberboard – a building and DIY sheet material commonly used in cabinetry, furniture and molding. As a material, MDF is extremely versatile and cost-effective, making it a great choice for a whole host of projects. MDF isn’t often used as a finish alone but is instead finished with veneer or laminate, giving the impression of real wood. Due to the smoothness of MDF, it can easily be painted, cut and shaped, making it an ideal material for decorative DIY projects.

So, first things first; what is MDF board, and what does MDF stand for? MDF is a medium-density fiberboard – a building and DIY sheet material commonly used in cabinetry, furniture and molding. As a material, MDF is extremely versatile and cost-effective, making it a great choice for a whole host of projects. MDF isn’t often used as a finish alone but is instead finished with veneer or laminate, giving the impression of real wood. Due to the smoothness of MDF, it can easily be painted, cut and shaped, making it an ideal material for decorative DIY projects.

What is MDF made from?

MDF is a sheet material rather than hardwood and is created by using heat and pressure to fuse together fine wood fiber and glue. The resulting sheet material is strong yet extremely easy to work with. Plus, it is environmentally friendly, created using recycled wood! Alongside MDF, you can also get low-density fiberboard and high-density fiberboard. Low-density fiberboard, also known as particleboard, is created with even smaller pieces of wood fused together. The result is cheaper but also harder to work with, as it is more prone to chipping or breaking. High-density fiberboard, or hardboard, is created with more heat and pressure to create a much stronger finish, however, this is reflected in the price. MDF sits as a happy medium between these two materials – cost-effective, strong, durable and versatile.

Advantages of MDF

- MDF is inexpensive, so it’s useful for most people looking for cheaper home décor materials.

- The recycling process is used to make MDF. Hence it is eco-friendly.

- Smooth surface.

- It can be easily painted.

- It offers a more realistic finish.

- Solid, flat, and dense material

- MDF is easier to drill and cut into without causing any damage.

Disadvantages of MDF

- MDF is not stronger than wood.

- When put under stress, MDF can easily split or crack.

- MDF can absorb water faster than wood. So, it is prone to swelling up and causing damage.

- MDF comes with VOC that contains urea-formaldehyde, which can be harmful to the eyes and lungs.

- During the production of MDF, there is a lot of dust released into the air, which can be harmful.

What is a Particle board?

Particle-board is another inexpensive product made using waste wood materials. It is made combining resin and sawdust that’s heat pressed together. Particle-boards are widely used to make low-end home décor furniture. It is also used as an underlying layer for countertops as well. Particle-board can be easily drilled into; however, it is subject to a certain level of tear-out. Laminate or veneer is used to finish a particle board’s surface to give it a better look. It is difficult to shape and mould a particle-board as it tends to break or chip.

Particle-board is another inexpensive product made using waste wood materials. It is made combining resin and sawdust that’s heat pressed together. Particle-boards are widely used to make low-end home décor furniture. It is also used as an underlying layer for countertops as well. Particle-board can be easily drilled into; however, it is subject to a certain level of tear-out. Laminate or veneer is used to finish a particle board’s surface to give it a better look. It is difficult to shape and mould a particle-board as it tends to break or chip.

Advantages of Particle-board

- One of the main advantages of a particle-board is that it is low in cost compared to other products like MDF, solid wood, and plywood.

- It is lightweight and can be easily carried and transported around

- When compared to MDF, it can hold nails and screws better.

- Easy to clean and maintain

- It can be easily drilled, cut, milled, painted, glued, etcetera.

- It’s an eco-friendly product made from waste-wood products such as sawdust, wood chips, and shavings.

- They do not come with natural defects like solid wood.

- Particle-boards come with soundproof properties, and that’s the reason they are a good choice for auditoriums, speakers, and theatres.

- The smooth and flat surface allows for easy sticking of veneer and laminate materials. Thin sheets of these materials can be easily glued onto the surface to add to its beauty.

Disadvantages of Particle-board

- Particle-boards are not strong enough compared to other types of home interior materials such as plywood and MDF. Since it’s low on strength, it should be handled with care as easily damaged.

- Particle-boards have low durability.

- It comes with a low resistance to moisture and humidity. It is one of the significant disadvantages of particle boards. Due to moisture, particle boards can expand.

- Not eco-friendly as some types of particle-boards are manufactured using a resin which can be harmful to health.

MDF Vs Particle-board: What is the Difference?

| MDF | Particle-board | |

| Look | MDF has a smooth finish as it consists of wood grains that are of the same size. | Particle-boards do not have a smooth surface as they consist of wood shavings and chips. |

| Density | MDF has a higher density level than particle-board. | Particle-boards have a lesser density level. |

| Strength | MDF is fairly stronger than particle-board. | Particle-board is not very strong. |

| Durability | MDF is quite durable. | Particle-boards are relatively less durable. |

| Weight | Heavier than particle boards | Lightweight. |

| Moisture | More resistance to water. | Less resistance to water. |

| Lifespan | MDF can remain in proper condition for up to 10 years. | Particle-boards can last for up to 25 years. |

| Price | Costlier than particle-board. | Cheaper. |

This was everything you need to know about MDF and particle board materials for home décor. When choosing these materials, make sure you select good quality materials that are long-lasting.

Common Practical Uses Of MDF Board (Medium Density Fiberboard) :-

Practical Uses of MFD are as follows, Due to the smoothness of Medium Density Fiberboard (MDF), it can be easily painted, cut, and shaped, creating it an outstanding mater Medium Density Fiberboard (MDF) is a specially engineered commodity that is generated from wood fibers.It is a dense commodity and has various uses in a variety of industries.Fiberboard is a well-built product and is often coated with a veneer and it can also contain secondary raw materials such as fibers from sugarcane and wood chipping.

1. Furniture :-

- This is an extremely versatile material to work with and the various practical uses for Medium Density Fiberboard (MDF) and what you can do with it.

- To begin with, several different furniture companies utilise specially assessed Medium Density Fiberboards and if you have always purchased an economical piece of furniture like a bookshelf or an entertainment center, therefore chances are they may be constructed from MDF.

- Several different economical furniture pieces are constructed from low to medium density fiberboard because this special product is easily manufactured and is inexpensive, which lowers the cost of manufacturing and production.

- Obtaining low-density fiberboard typically decreases the costs connected with manufacturing furniture and it is a very popular material that is used in the creation of prefabricated furniture.

- Companies like IKEA and different big store companies give products that are manufactured from this material.

2. Cabinetry :-

- An additional thing that normal density fiberboard is known for is home interior cabinetry.

- It is most common to discover cabinets made of fiberboard and then completed with solid wood laminate on top.

- Home interior commodities like kitchen cabinets and shelving units are generally built from Medium Density Fiberboard(MDF) and this also contains doors, moldings, and sometimes even flooring such as wood impact laminates.

- There are several different applications that can be combined with using Medium Density Fiberboard (MDF) and these are only limited examples of how it is utilised in home interiors.

3. Fire Resistance :-

- One interesting usage for medium density fiberboard that several people may not be conscious of is its fire retardant capabilities.

- Specific buildings and structures expect the use of fire retardant MDF Board in their construction.

- This type of fiberboard is perceived to be used in the construction of commercial buildings which contain stores and offices and different buildings that must fulfill certain building legislation and requirements for safety.

- Some homeowners select to utilize fire retardant MDF Board in the construction of the new homes as well as to furnish further safety from any possible fires spreading.

4. Vapour Repulsion :-

- Medium-density fibreboard can be also utilised as a vapour obstacle and insulation for both residences and commercial buildings.

- This is because it has durability and procedure that makes it an excellent vapour obstacle when utilised with additional vapour repellant products.

- This type of wood is prepared to deal with the big periods of moisture and drying out without occurring damaged like shrinking or going through the method of rotting.

- It can be an act as a vapour obstacle and it can also give insulation and avoid heat loss which would finally help with lowering heating expenses and electrical bills.

5. Soundproofing:

- This may not be as widely recognised, but fiberboard can also give soundproofing and reduce the ability of sound to travel.

- Several speaker manufacturers utilise medium-density fiberboard or particle board because it consumes sound and prevents the vibration from inside the speaker case.

- This wood commodity can also be utilised in media rooms, walls of apartment buildings and offices as well as the floor underlayment to enable minimize sound disruptions and noise pollution.

- Several different contractors and building firms use MDF Board for this specific purpose during construction for the requisition of decreasing noise and sound traveling.

6. Roofing:

- Another interesting truth about the versatility know that fiberboard is its usage for around the home both the inside and outside.

- Fiberboard can be utilised for all types of housing desires comprising roofing materials for low sloped roofs.

- Medium Density Fiberboard is an outstanding material that can be utilised as backing for shingles of any type of roof.

- You can also utilise it as sheathing for walls inside your home.

- Medium Density Fiberboard is extremely durable as well as flexible which provides it multiple applications when it comes to a family home both in the interior and exterior.

- Finally, medium density fibreboard is a top-notch solution with many various uses and aspects that it can be utilised for.

- This list of popular practical usages of Medium Density Fiberboard (MDF) is just a brief example and there are plenty of more uses of Medium Density Fiberboard (MDF) that can be utilised for.

- It will continue to be an inexpensive option rather than buying timber commodities such as plywood and with its various uses, it will ever be a well known and widely utilised material in the fabrication of furniture all the path to the construction of buildings and homes.